Types of 3D printing processes

I. Stereolithography (SLA) — High Precision and Detailed Representation

Process Name: Stereolithography

Working Principle: As the world’s first 3D printing technology, it employs a UV laser beam of a specific wavelength to precisely scan the surface of liquid photopolymer resin along a predefined path. This triggers an instant photopolymerization reaction, solidifying the material into shape. After completing one layer, the build platform lowers by the thickness of one layer. As the squeegee reapplies resin, the laser scans the next layer. This cycle repeats until the entire object is completed.

Primary Materials: Photopolymer resins. These materials remain liquid before exposure and exhibit distinct properties after curing, such as standard resins, high-toughness resins, transparent resins, heat-resistant resins, and even castable resins.

Features and Applications: SLA is renowned for its exceptional printing precision and outstanding surface smoothness, making it ideal for producing models demanding intricate details. Applications include prototype validation, jewelry casting, dental models, precision components, and rapid prototyping for small-batch molds.

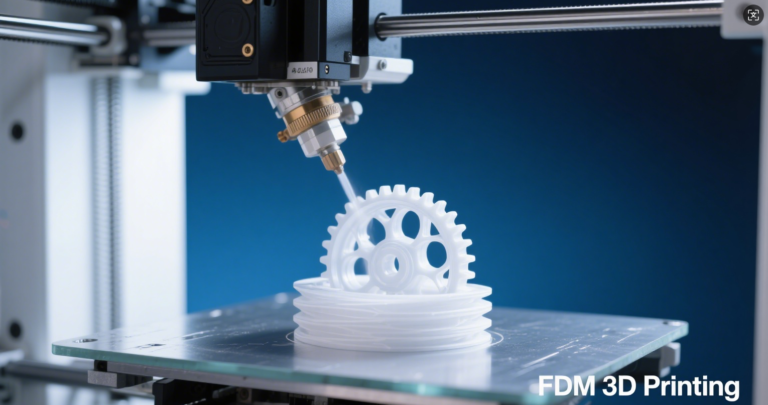

II. Fused Deposition Modeling (FDM) — Desktop 3D Printing

Process Name: Fused Deposition Modeling (FDM)

Working Principle: This is currently the most widespread and popular consumer-grade 3D printing technology. It feeds spooled thermoplastic filament (wire) into a heated nozzle (extruder) where it melts. The nozzle moves along computer-programmed paths, extruding and depositing the molten material onto the build platform. The extruded material instantly cools and solidifies, bonding firmly to the previous layer. Layers are stacked sequentially to form the final object.

Primary Materials: A wide variety of thermoplastic filaments, most commonly PLA (polylactic acid) (easy to print, eco-friendly), ABS (acrylonitrile butadiene styrene) (high strength, heat-resistant), as well as PETG, TPU (flexible materials), nylon, etc.

Features and Applications: FDM technology’s low cost, ease of operation, and diverse material options make it the preferred choice for hobbyists, educators, and startups. It is widely used for proof-of-concepts, functional prototyping, educational models, customized tools and fixtures, and simple end-use parts.

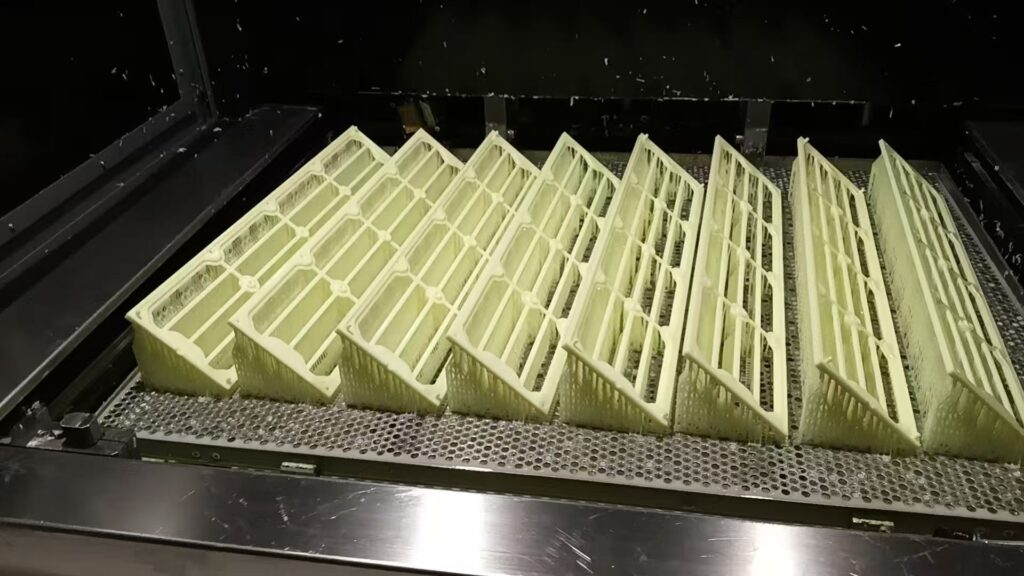

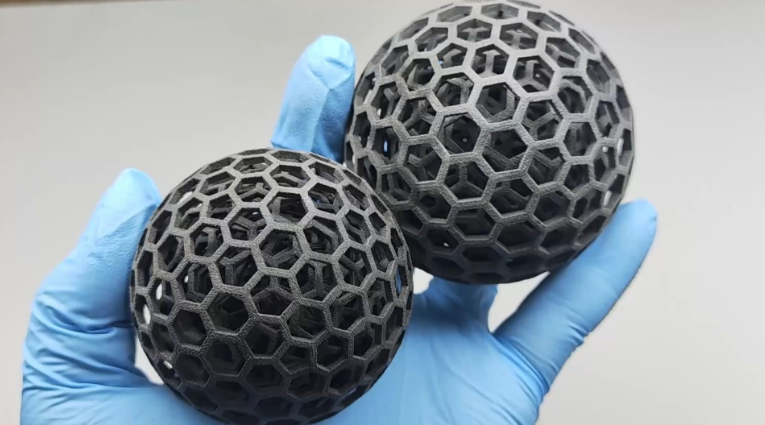

III. Selective Laser Sintering (SLS) — Manufacturing Functional Parts

Process Name: Selective Laser Sintering (SLS)

Working Principle: This technology employs a high-power laser as its energy source. At the start of printing, the powder hopper’s piston rises, and a powder spreading roller evenly deposits a thin layer of powder material onto the build platform. The laser beam selectively scans the powder layer according to cross-sectional data, sintering the particles to fuse them. After completing one layer, the build platform descends by the thickness of one layer, powder is reapplied, and the process repeats until the part is finished. Unsintered powder naturally forms support structures, which can be recycled after printing.

Primary Materials: Primarily nylon (PA) and its composites (e.g., nylon mixed with glass beads or aluminum powder)

Features and Applications: SLS’s greatest advantage is eliminating the need for support structures, enabling the production of highly complex geometries and moving parts. Its finished products exhibit excellent mechanical properties and functionality, allowing direct use as end-use parts. It is widely applied in aerospace, automotive manufacturing, medical devices (e.g., prosthetics), and other fields.

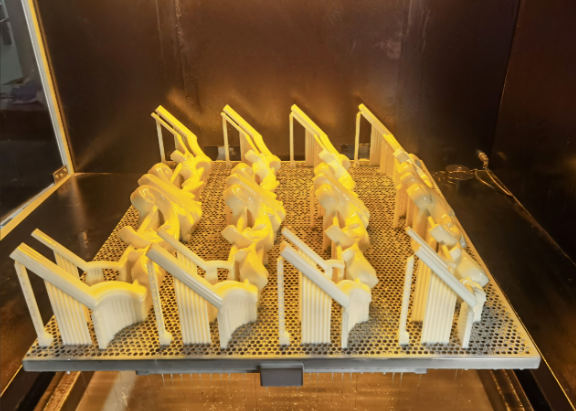

IV. Multi Jet Fusion (MJF) — High Efficiency

Process Name: Multi Jet Fusion (MJF)

Working Principle: Similar to SLS, MJF employs powder bed technology but utilizes a different heat source. First, a powder spreading device deposits a layer of nylon powder onto the build platform. Then, an inkjet array selectively sprays two agents onto the powder surface: a melting agent (in areas requiring solidification) and a detail agent (applied to edge regions to enhance precision). Finally, an infrared energy source scans the entire platform. Areas sprayed with the melting agent absorb energy, rapidly melting and solidifying, while powder in other regions remains untouched.

Primary Materials: Primarily nylon (PA12, PA11).

Characteristics & Applications: MJF achieves significantly faster printing speeds than SLS because it heats an entire layer at once rather than scanning point by point. It strikes a good balance between detail rendering, material properties, and cost efficiency, making it highly suitable for producing functional parts in small to medium batches.

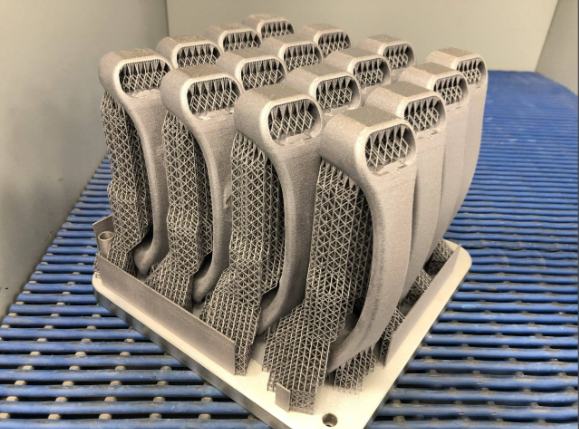

V. Metal 3D Printing (SLM/DMLS) — High-End Manufacturing

Process Name: Selective Laser Melting (SLM) / Direct Metal Laser Sintering (DMLS)

Working Principle: Both operate similarly within an inert gas-filled build chamber, using high-energy fiber lasers to melt metal powder particles fully, achieving metallurgical bonding through layer-by-layer formation. SLM typically achieves full melting, while DMLS sinter to near-full density; however, the terms are often used interchangeably in the industry.

Primary Materials: Various metal powders, including titanium alloys (Ti6Al4V), aluminum alloys (AlSi10Mg), stainless steel (316L), tool steel, cobalt-chromium alloys, and nickel-based high-temperature alloys.

Characteristics and Applications: This represents the ultimate technology for directly manufacturing highly complex, high-strength metal parts. It enables the creation of lightweight topologically optimized structures and internal conformal cooling channels unattainable through traditional machining or casting. It holds irreplaceable value in aerospace, medical implants (e.g., hip replacements), high-end automotive components, and mold manufacturing.

In summary, 3D printing is not a single technology but a diverse family of techniques. From accessible FDM to precise SLA, from robust SLS/MJF to cutting-edge metal printing, each technology excels in distinct application scenarios through its unique processes and material systems. With ongoing material development and process optimization, 3D printing will continue to reshape how we design and manufacture.