How to level a 3D printer bed

Essential 3D Printing Skill: Step-by-Step Guide to Precisely Leveling Your 3D Printer Bed and Saying Goodbye to Failed First Layers

“How to level a 3D printer bed” is the first—and most crucial—search term countless beginners look up after getting started. Warped prints, failed first layers, rough and uneven bases… These common frustrations for newcomers almost always stem from an uneven build plate.

Platform leveling (also known as bed leveling) is the cornerstone of successful 3D printing. It ensures the nozzle maintains a perfect and consistent distance from the print bed across the entire print surface. Today, this ultra-detailed guide will serve as your personal coach, guiding you from theory to practice to conquer this “roadblock” once and for all, enabling you to effortlessly print a perfect first layer.

Why is leveling so crucial?

Imagine writing with a pen on paper. If the nib is too far from the surface, your writing will be spotty; if it presses too hard, ink will smear or even tear the paper. The 3D printer’s nozzle acts like the pen tip, and the print bed is the paper.

Nozzle too high: Extruded filament cannot press firmly against the bed, resulting in poor adhesion, stringing, shifting, and entire prints detaching.

Nozzle too low: The nozzle scrapes the platform, obstructing proper extrusion. This results in an extremely thin first layer or even nozzle clogging.

Only when the distance is just right can the filament be gently “flattened” and firmly bonded to the platform. This creates a solid foundation for subsequent layers to build upon.

Preparation Before Leveling

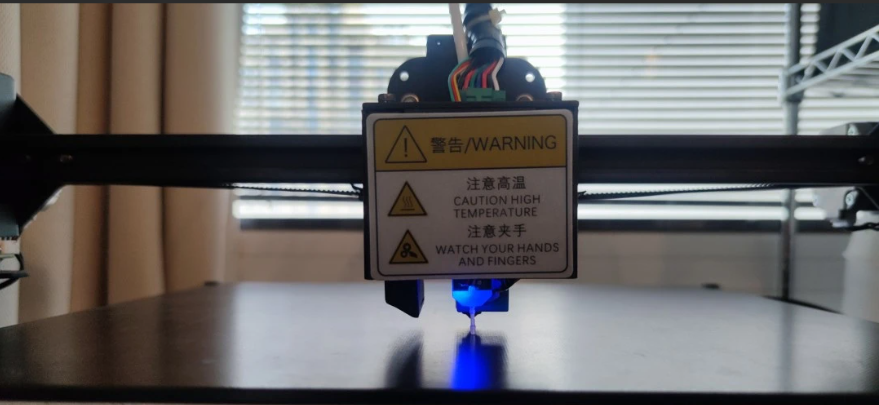

Heat the Printer: Before final leveling, ensure the print nozzle and heated bed are preheated to your standard printing temperature (e.g., set to nozzle 200°C, bed 60°C for PLA material). Metal components expand with heat, causing a cold-leveled platform to become uneven once heated.

Clean the Platform: Wipe the print bed with alcohol or a lint-free cloth to remove grease, dust, or previous print residue.

Prepare Tools: A standard A4 copy paper sheet is a leveling essential. Its thickness (approximately 0.1mm) provides the ideal gap between the nozzle and platform.

Step-by-Step Guide: Four-Corner Leveling Method (Manual Leveling)

Most entry-level printers use the classic “four-corner leveling method.” Follow these steps:

“Auto Home” Operation: In the printer control menu, select “Auto Home” or “Return to Home.” The print head will move to its initial position.

Disable Steppers: After homing, it’s crucial to find “Disable Steppers” or “Release Steppers” in the control menu. This allows manual movement of the print head and bed.

Move Nozzle to First Corner: Gently position the print head near the front-left corner of the bed. Ensure the nozzle is directly above the leveling screw.

Perform the “Paper Test”:

Place a prepared sheet of A4 paper between the nozzle and the platform.

Manually rotate the leveling knob beneath the platform (typically a spring-loaded screw). Turning clockwise usually raises the platform (decreasing the gap), while turning counterclockwise lowers it (increasing the gap).

Pull the paper back and forth while slowly adjusting the knob. Your goal is to achieve a “slightly resistant” gap between the nozzle and the platform. You should feel the paper being lightly scraped as it moves, but not to the point of jamming or tearing. This sensation requires a bit of practice to master.

Repeat for the other three corners: Move the print head to the front-right corner, rear-right corner, and rear-left corner in sequence. Perform the paper test and adjustment from step 4 for each corner. Note: When moving the print head, take care not to disturb the platform height you’ve already set.

Re-check and fine-tune: After completing one full rotation, you must re-check the first corner. Adjusting one corner slightly affects the other three! You need to follow a “diagonal” sequence like tightening car tire lug nuts (e.g., front left -> rear right -> front right -> rear left) for multiple rounds of adjustments until all four corners no longer require tweaking and achieve the same “slight resistance” feel.

Advanced Technique: Using Auxiliary Tools

Print a leveling test model: In slicing software, draw a single thin layer covering most of the bed (or download the “Bed Level Test” model from Thingiverse). Observe the printed lines:

Lines are too thin, transparent, or broken -> Nozzle is too close in that area.

Lines are rounded, non-adhering, and easily pushed away -> Nozzle is too far in this area.

Lines are flat and uniformly adhered -> Perfect!

Based on the print results, fine-tune the corresponding corner knobs during printing.

Modern Solution: Automatic Bed Leveling (ABL)

If purchasing a new printer, we strongly recommend models with automatic bed leveling (ABL) features, such as BLTouch or CRTouch sensors. These sensors automatically scan multiple points on the bed to create a “topographic map,” enabling the printer to automatically compensate for minor unevenness during printing.

Note: ABL is not a universal solution and cannot replace manual leveling. You still need to perform relatively accurate manual leveling (“rough leveling”) first, then let the ABL system handle the remaining height differences (“fine leveling”). However, it significantly lowers the learning curve for beginners and greatly improves print success rates.

Common Issues & Final Checklist

Q: I’ve leveled the bed, but the first layer still doesn’t stick?

A: Check platform cleanliness (wipe with alcohol), print temperature (increase bed temperature if needed), and first layer print speed (recommended ≤20mm/s).

Q: My leveling knob loosened on its own?

A: Ensure the spring has sufficient preload. You can print and install a “Leveling Knob Lock Nut” for reinforcement.

Final Checklist:

Nozzle and heated bed are preheated to operating temperature.

Build plate is clean.

All four corners pass the “slight resistance” paper test.

Multiple diagonal checks confirm consistent leveling across all corners.

A test model has been printed for final verification.

Conclusion-How to level a 3D printer bed

Mastering manual bed leveling is a must-learn skill for every 3D printing enthusiast. While it may seem tedious at first, once you grasp the principles and techniques, the entire process takes only a few minutes. A perfectly leveled platform is the absolute prerequisite for high-quality prints. Now, gather your confidence, follow the steps, and you’ll soon bid farewell to warping woes, enjoying the satisfaction of a flawless first layer!

Happy 3D printing!

Recommended Reading: How to get started with 3D printing