Can you 3D print metal materials?

This article delves into the question, “Can you 3D print metal materials?” It provides a detailed overview of the three mainstream technologies in metal 3D printing (SLM, DMLS, Binder Jetting), analyzing their working principles, material selection, industry applications, and the advantages and challenges they present relative to traditional manufacturing.

Keywords: Metal 3D printing, 3D printing metals, SLM technology, DMLS technology, binder jetting, additive manufacturing, 3D printing services, 3D printing costs

“Can you 3D print metal materials?”—This is one of the most common questions asked by those new to 3D printing technology. The answer is not only yes, but metal 3D printing is fundamentally transforming high-end manufacturing sectors like aerospace, medical, and automotive. It’s no longer a laboratory concept but is actively producing high-strength, highly complex functional end-use parts. This article will take you deep into the fascinating world of metal 3D printing.

How Does Metal 3D Printing Work? Unveiling Mainstream Technologies

Unlike common desktop FDM printers that use plastic filament, metal 3D printing typically employs more advanced techniques, primarily including the following:

- SLM (Selective Laser Melting)

This is the most common metal 3D printing technology. It employs a high-power precision laser beam to selectively scan a bed of metal powder within a forming chamber filled with inert gas. The laser’s energy is sufficient to fully melt the metal powder (rather than merely sintering it), fusing it into a dense solid metal layer. After one layer is completed, a powder spreading roller deposits a fresh layer of powder. The laser then scans and melts the next layer, firmly bonding it to the previous one. This cycle repeats until the entire part is finished. Parts produced via SLM exhibit excellent mechanical properties, approaching or even surpassing those of traditional forging. - DMLS (Direct Metal Laser Sintering)

DMLS operates on principles very similar to SLM and is often used interchangeably. The subtle distinction lies in the DMLS process, primarily sintering metal powder particles together at high temperatures rather than fully melting them. However, today, the end results produced by both technologies are remarkably close, capable of manufacturing extremely robust and dense parts. - Binder Jetting

This is a relatively newer technology, with a process similar to inkjet printing. A print head moves across a powder bed, selectively jetting a liquid binder to bond metal particles together, forming a layer of “green part.” After completion, the platform lowers, deposits a fresh layer of powder, and repeats the process. The printed part requires post-processing, typically sintering in a high-temperature furnace. This causes the binder to evaporate while the metal particles fuse together, achieving the final strength.

What metal materials can be printed?

The material library for metal 3D printing is extensive, covering nearly all common metals used in engineering:

Titanium Alloy (Ti6Al4V): Preferred for aerospace and medical implants (e.g., joints, bone plates) due to its high strength, lightweight properties, and excellent biocompatibility.

Aluminum Alloy: Lightweight yet strong, widely used in automotive and aerospace industries.

Stainless steel (316L): Offers good corrosion resistance and mechanical properties for functional prototypes, tools, and end-use parts.

Nickel-based superalloys (e.g., Inconel): Provide exceptional high-temperature and corrosion resistance, making them ideal for jet engine and gas turbine components.

Cobalt-chromium alloys: Commonly used in dental and medical applications for crowns, prosthetics, etc.

Tool steel: Used for manufacturing injection molds with complex internal cooling channels.

Advantages and Challenges of Metal 3D Printing

Advantages:

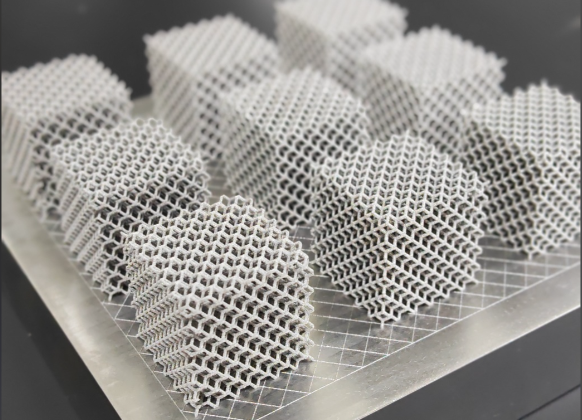

Design Freedom: Enables the creation of complex geometries, internal cavities, and lattice structures unattainable through traditional subtractive manufacturing (e.g., milling).

Monolithic Manufacturing: Allows printing components in a single piece that would otherwise require assembly from multiple parts, reducing assembly steps and potential failure points.

Weight Reduction: Significantly reduces part weight while maintaining strength through topology optimization and lattice structures.

On-Demand Production: Ideal for small-batch, customized parts like personalized medical implants, eliminating the need for costly molds.

Challenges:

High Cost: Both equipment and metal powder materials are extremely expensive.

Post-Processing Requirements: Printed parts typically require support removal, hot isostatic pressing (HIP), and surface finishing.

Technical Barriers: Operators must possess deep expertise in materials and processes.

Size Constraints: The build chamber limits the maximum volume of printable parts.

Conclusion

Therefore, in response to the question “Can you 3D print metal materials?”, we can not only answer with a resounding “Yes,” but further assert that it is emerging as a transformative technology in modern manufacturing. While currently primarily applied in high-end industrial sectors, as the technology continues to advance and costs decrease, metal 3D printing will inevitably expand into broader industries, unlocking unprecedented design and manufacturing possibilities.