Applications of 3D Printing in Semiconductor Manufacturing

In semiconductor manufacturing, 3D printing technology has penetrated multiple critical stages due to its high precision and manufacturing flexibility, driving the industry toward miniaturization, integration, and efficiency. Below are its primary application areas and specific implementations:

- Prototyping and Rapid Validation

Application Scenario: Traditional semiconductor prototyping relies on complex processes like lithography and etching, resulting in lengthy cycles and high costs. 3D printing enables rapid production of high-precision prototypes, accelerating design iterations.

Case Study: A Tsinghua University team achieved 3D nanoprinting of semiconductor quantum dots using photochemical bonding technology, reaching a resolution of 150 nanometers. This allows direct validation of three-dimensional optoelectronic chip designs, shortening R&D cycles. - Complex Structure Fabrication

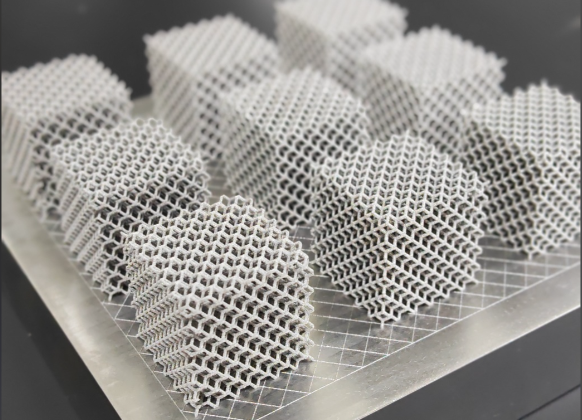

Microelectromechanical Systems (MEMS): 3D printing enables the fabrication of minute interconnect structures, integrated sensors, and actuators unattainable via traditional methods. For instance, Swiss firm Exaddon AG printed micro-nano probe arrays with sub-20-micron pitch, significantly boosting testing efficiency.

3D Integrated Circuits: Layer-by-layer printing achieves vertical stacking of transistors and interconnect layers, overcoming limitations of 2D planar integration. - Packaging and Testing

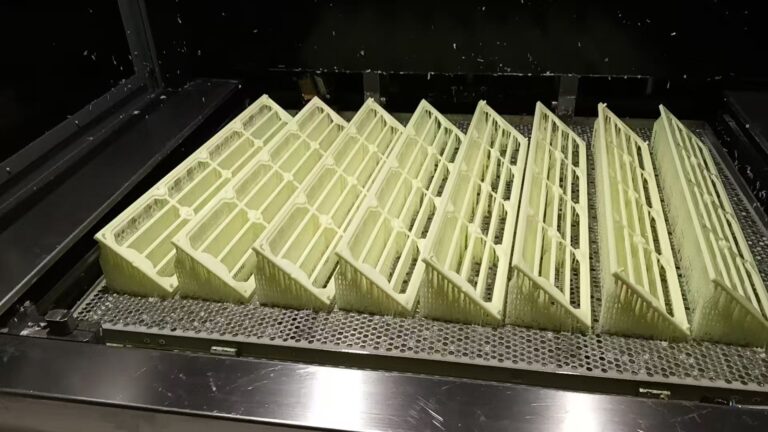

Advanced Packaging Technologies: 3D printing supports 2.5D/3D stacked packaging, optimizing thermal management and signal transmission. For instance, Exaddon AG’s μAM technology directly prints highly conductive structures on micro-PCBs, shortening connection distances and reducing latency.

Test Structures: Printing high-precision test probes and fixtures, such as MicroLED test arrays with 18.5-micrometer pitch, enhances testing accuracy and efficiency. - Manufacturing Equipment and Tool Optimization

Thermal Management Components: 3D-printed wafer stages and heat exchangers with conformal cooling channels enhance equipment precision and stability. 3D Systems achieved an 83% reduction in thermal variation for wafer stages through topology optimization, reaching 1-2 nm precision.

Lightweight Components: ASML lithography machine chucks reduced weight by 30% via 3D printing, improving positioning speed and throughput. - Novel Material and Device Development

Ceramic Applications: 3D-printed silicon nitride and aluminum oxide ceramic components for high-temperature, high-power semiconductor packaging. For instance, QY Technology’s ceramic thermal management parts exhibit superior thermal conductivity for extreme environments.

Heterogeneous Material Integration: 3D printing enables hybrid printing of semiconductors with metals and polymers, expanding device functionality. - Small-Batch Customized Production

Application Scenarios: For research or small-batch high-end chip demands, 3D printing reduces mold costs and enables rapid customization. For instance, printing photonic crystal sensors with specific wavelengths meets personalized requirements.

Technical Challenges and Future Trends

Precision and Materials: Achieving nanoscale printing accuracy and compatibility with more semiconductor materials (e.g., silicon, compound semiconductors) are key breakthroughs needed.

Industrialization Path: Optimizing printing speed, reducing costs, and integrating with existing processes (e.g., lithography) are essential.

Industry Landscape: Giants like Nikon and ASML are accelerating technology integration through acquisitions of 3D printing firms (e.g., SLM Solutions), driving semiconductor manufacturing innovation.

Summary: 3D printing is reshaping semiconductor processes, demonstrating advantages in the fabrication of complex structures, thermal management optimization, and material innovation—from prototyping to mass production and packaging. As technology matures, it is poised to play a greater role in fields such as 3D integrated chips and quantum devices.