Mainstream Support Structures in 3D Printing

The Role of Support Structures in Metal 3D Printing

- Mechanical Support and Warpage Prevention

This is the most intuitive function of support.

Overcoming Gravity: Used to support overhanging structures. When printing angles are less than 45 degrees (this angle varies by material and process), molten metal would sag under gravity without supports, leading to print failure, surface roughness, or structural collapse.

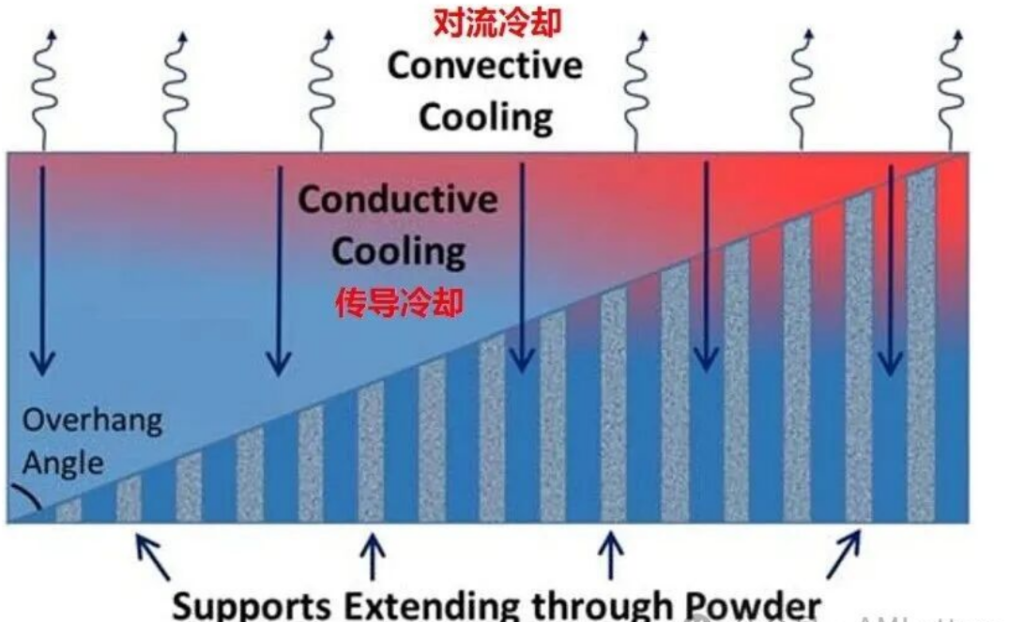

Resisting Stress: Significant residual thermal stress exists during metal printing. Materials are instantly melted by the laser and rapidly cooled to solidify. This abrupt thermal cycling causes part shrinkage and deformation. Support structures firmly “anchor” the part to the build plate, providing rigid constraints that effectively resist shrinkage stress. This prevents warping, cracking, or detachment from the build plate. - Thermal Conductivity and Heat Dissipation

This is a critical yet often overlooked function.

Heat Pathways: During printing, the laser scanning area reaches extremely high temperatures. Support structures act as additional heat pathways, rapidly conducting accumulated heat to the substrate below and throughout the build chamber, preventing localized thermal buildup.

Preventing Overheating: Without supports, delicate features (like isolated islands) or thin-walled structures may overheat due to insufficient heat dissipation. This can cause powder adhesion, balling effects, or even burn damage, severely compromising print quality. Support structures function like “heat sinks” for these areas.

Detailed Analysis of Mainstream 3D Printing Support Structures

- Solid Supports: Rigid Assurance for High-Stress Scenarios

Solid supports are dense metal structures matching the part’s base material, designed to withstand high-stress conditions. For aerospace load-bearing components, heavy machinery parts, and other scenarios where “stress concentration during printing can cause fractures,” their high rigidity prevents block supports from tearing or detaching. This fundamentally eliminates print failures.

Design and Import Logic: These supports are typically co-designed with parts in CAD software like UG or SolidWorks. To reduce stress concentration at substrate contact points, chamfers are applied where supports connect to substrates. When imported into preprocessing software like Magics, solid supports are integrated as a “part-support unified model.” Subsequent removal via wire cutting (for titanium alloys, high-temperature alloys) or precision machining prevents damage to the part itself.

To enhance forming efficiency, the current mainstream approach involves “separately importing parts and solid supports into preprocessing software.”: Set standard scanning parameters for the part based on precision requirements. Since supports require complete removal later, omit the contour scanning step and appropriately increase laser scanning speed (e.g., from 1000 mm/s to 1500 mm/s in SLM processes). This maintains support strength while reducing printing time by over 30%.

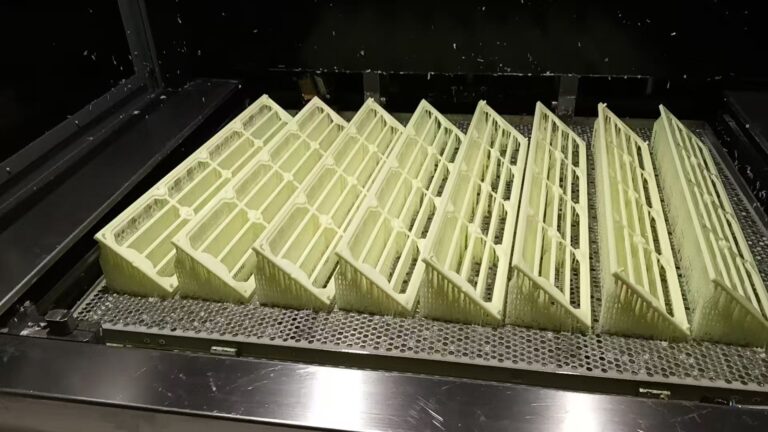

- Block Supports: The “Universal Choice” for Large Overhangs

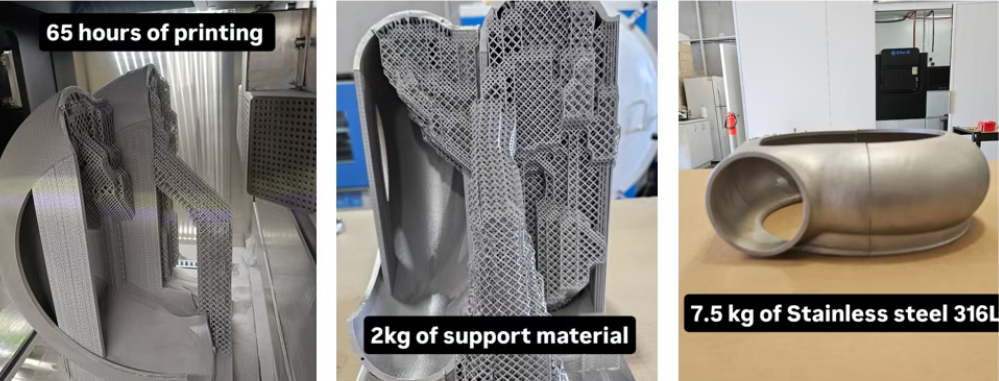

Block supports are the most widely used foundational support structures in metal 3D printing (e.g., SLM, LPBF). Typically, solid or high-density mesh blocks, their core advantage lies in “large contact area and uniform support force”—enabling stable load-bearing for large overhanging regions (such as inclined surfaces of large thin-walled parts or annular cavities in monolithic combustion chambers) and preventing gravitational collapse of molten metal.

However, limitations exist: high-density structures waste metal powder (consuming over 40% more material than hollow supports), while extensive contact between supports and parts complicates post-processing. Mechanical grinding risks scratching surfaces, and chemical etching requires extended time, making them more suitable for non-critical parts with lower post-processing efficiency demands.

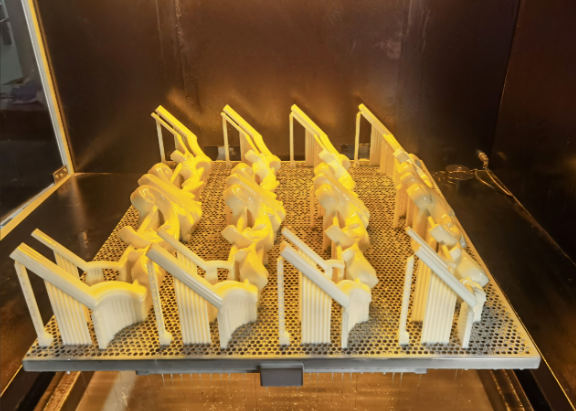

- Escape-stage Support (E-stage Support): The “Damage-Free Solution” for Precision Parts

E-stage Support is specifically engineered for precision parts vulnerable to post-processing damage. Its core innovation lies in a dual-layer design featuring a “rigid main body + fragile connection”:

Support Body: Consistent with traditional block/mesh supports, it employs a high-density structure providing sufficient mechanical support and heat dissipation channels. This ensures parts remain free from warping or deformation during printing, making it suitable for scenarios demanding high forming stability, such as medical implants and optical components.

Fragile Connection Points: The “essence” of E-stage support lies in its contact points between the support body and the part. Instead of full contact surfaces, these points consist of minute contact points or fine lines with diameters of 0.1-0.3mm. Post-processing requires no forceful tool removal. Mere gentle external force (e.g., tweezers or ultrasonic vibration) fractures these connection points, perfectly preserving delicate part structures like implant threads or sensor micro-pores.

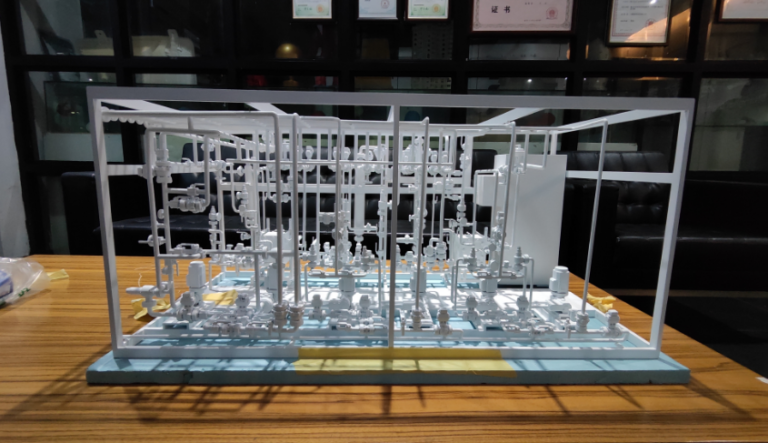

- Dental-Specific Hollow Tapered Supports: Millimeter-Level “Customized Adaptation”

In dental metal 3D printing applications such as titanium alloy/cobalt-chromium alloy dentures and implant abutments, hollow tapered supports represent the optimal solution, balancing “part characteristics, process requirements, and post-processing standards.”

The core challenge for dental parts lies in “millimeter-level dimensions + complex intricate structures” (e.g., occlusal surfaces of crowns, internal threads of implants), which hollow conical supports specifically address. The minimal contact area design (support contact point diameter of only 0.2-0.5mm) prevents obstruction of critical functional surfaces. During post-processing, these supports can be rapidly and easily removed with minimal residue and virtually no surface damage, meeting the quality requirements for oral implants.

Support structures in metal 3D printing may appear as “auxiliary elements concealed behind parts.” Still, they are, in fact, the “critical pivot” that determines print success, anchors part quality, and controls production costs. From fundamental functions like resisting thermal stress and supporting overhanging structures, to solid supports for high-stress aerospace components and hollow conical supports for precision dental parts, to E-stage supports focused on damage-free post-processing—the design and selection of each structure represents a deep alignment between “process characteristics, part requirements, and cost-effectiveness.” — Selecting the right support not only prevents print failures caused by warping or collapse but also minimizes post-processing losses and material waste, even clearing obstacles for mass production of high-value parts.

As metal 3D printing advances into more complex and higher-precision applications, support structure innovations—such as topology-optimized supports, AI-driven automatic support parameter optimization, and lightweight hollow designs—will continue to evolve. For practitioners, understanding the “functional logic” of supports and mastering selection strategies for different scenarios is not only fundamental to improving print efficiency but also key to unlocking the full value of metal 3D printing technology. In the future, support structures will deeply integrate with materials, processes, and post-processing, becoming a vital force in driving industry cost reduction, efficiency gains, and expanding application boundaries.