What is 3D printing? 3D printing is a technology that creates three-dimensional objects by layering materials based on a digital model file.

What is 3d printing-The Difference Between 3D Printing and Traditional Manufacturing

Traditional manufacturing (such as carving): Involves removing excess material from a solid block (e.g., wood, stone) through cutting and shaping to achieve the desired form. This is a “subtractive” process.

3D Printing:

This process builds objects from scratch by incrementally adding material layer by layer. It is an “additive” manufacturing process. Consequently, the academic term for 3D printing is “additive manufacturing.”

What is 3d printing-How Does 3D Printing Work?

A standard 3D printing process typically involves the following four steps:

Creating a 3D Model:

First, you need a 3D digital model of the object. This is akin to needing blueprints for building a house. Models can be obtained primarily through:

Designing it yourself: Using professional software (like SolidWorks, Fusion 360, Blender) or user-friendly online tools (such as Tinkercad).

Downloading Models:

Acquire pre-designed model files from online model-sharing communities like Thingiverse or Cults3D.

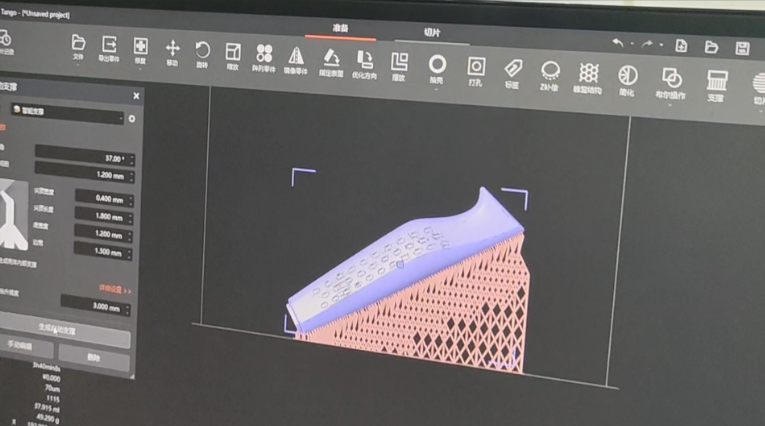

Slicing:

3D printers cannot directly interpret 3D models. You must process the model using slicing software (e.g., Cura, PrusaSlicer).

Slicing software “slices” the 3D model into hundreds or even thousands of thin cross-sections (like slicing a sausage into thin slices).

It then generates a special code (typically G-code) containing detailed instructions for each layer—including print paths, speed, temperature, and other settings—and sends it to the 3D printer.

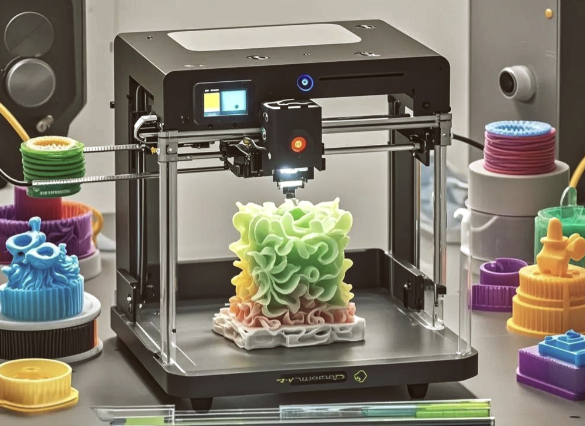

3D Printing:

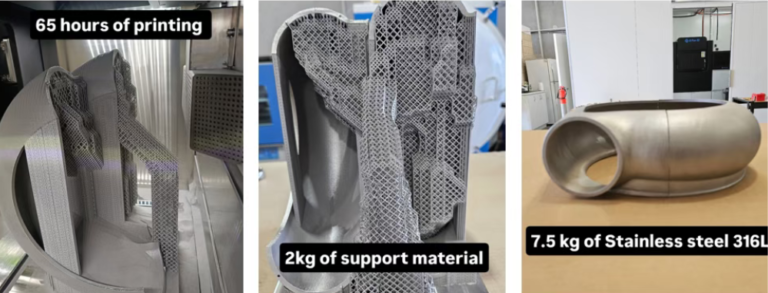

Upon receiving instructions, the 3D printer begins working. The print head deposits material (usually melted plastic filament) layer by layer along the path planned by the slicing software, with each layer firmly bonding to the next. This process continues until the entire object is completed.

Post-processing:

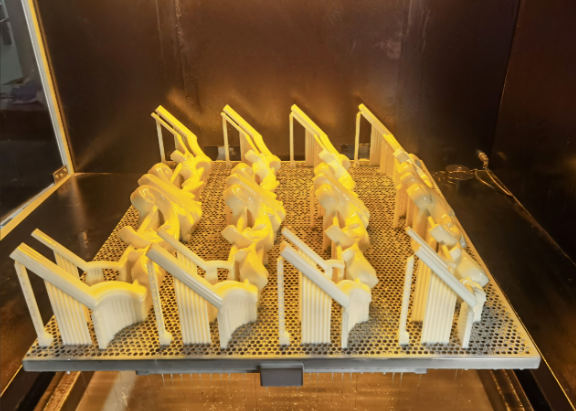

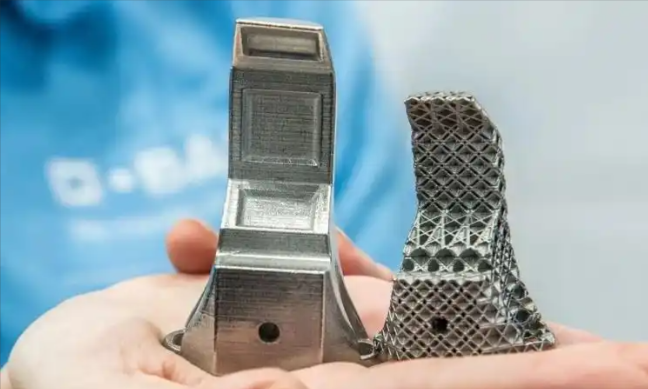

After printing, some objects may require additional steps, such as:

Removing support structures (temporary supports used for overhanging parts).

Sanding to achieve a smoother surface.

Applying paint or coating.

For metal prints, heat treatment may be necessary to enhance strength.

What is 3d printing-Mainstream Types of 3D Printing Technology

Based on the materials used and the forming principles, several primary technologies can be distinguished:

FDM (Fused Deposition Modeling): This is the most common and household-friendly technology. It works by heating and extruding plastic filament (such as PLA or ABS) through a nozzle, layering it to form the object. Most desktop 3D printers we encounter fall into this category.

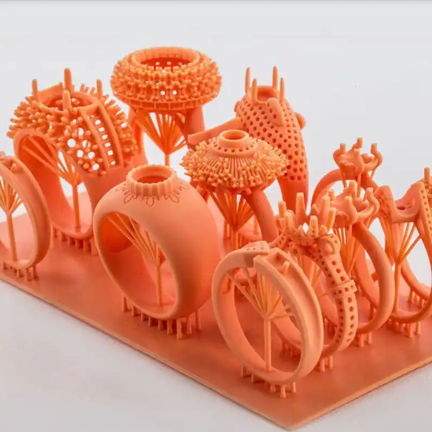

SLA/DLP (Stereolithography/Digital Light Processing): This method uses a liquid resin (photopolymer) that reacts to ultraviolet light. A specific wavelength of light (from a laser or projector) is directed at the resin surface, causing it to cure layer by layer. This technology offers exceptional precision and is often used for printing highly detailed models, jewelry, and similar items.

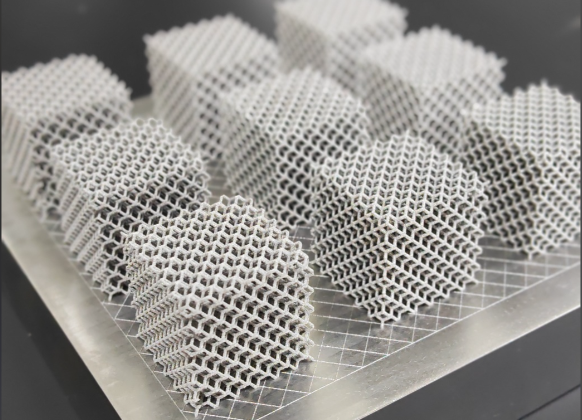

SLS (Selective Laser Sintering): A high-power laser fuses microscopic particles of nylon, metal, or ceramic powder. This technology produces high-strength parts without requiring support structures and is primarily used in industrial manufacturing for functional components.

What is 3d printing-Applications of 3D Printing

3D printing has an extensive range of applications, permeating nearly every industry:

Prototyping and Product Development: Engineers and designers can rapidly and cost-effectively print product prototypes for testing and validation, significantly shortening development cycles.

Education and Research: Printing instructional models (such as molecular structures, human organs, historical artifacts) provides students with a more intuitive understanding.

Medical Field: Production of customized surgical guides, prosthetics, dental appliances, and even printed artificial tissues and organs (bioprinting).

Aerospace and Automotive: Manufacturing lightweight, structurally complex components like engine blades and bespoke tools.

Construction Industry: Printing intricate architectural models and even direct components for building structures.

Art and Fashion: Creating complex sculptures, personalized jewelry, and bespoke apparel and footwear.

Daily Life: Printing phone cases, toys, home decor items, and more to meet personalized needs.