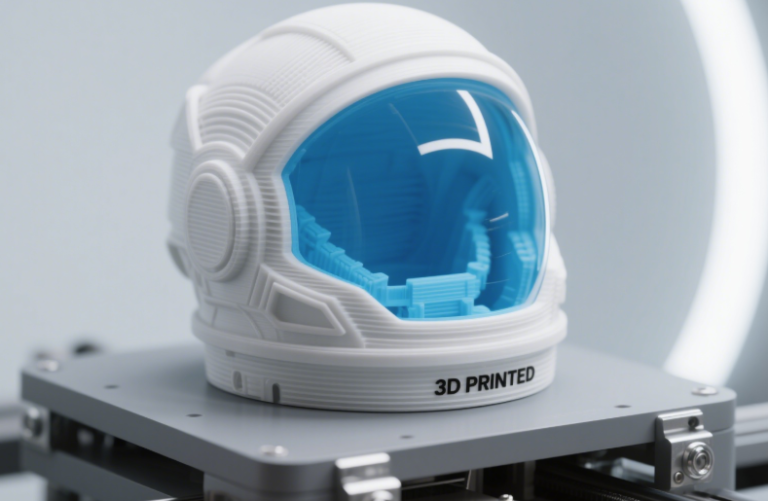

Can 3D-printed shoes really be worn?

The answer is a resounding yes! Not only are they wearable, but they may also be more comfortable and personalized than traditional shoes. Next, we’ll comprehensively analyze the feasibility of 3D-printed shoes from the perspectives of materials, manufacturing processes, and application directions.

Materials: The Leap from “Plastic-Like” to “Tech-Forward”

Many people associate 3D printing materials with hard, brittle plastics. But today, shoe printing materials have evolved significantly:

Flexible Photopolymer Resin:

Offers excellent elasticity and toughness with a rubber-like feel. It can be repeatedly bent without deformation or cracking and feels comfortable against skin.

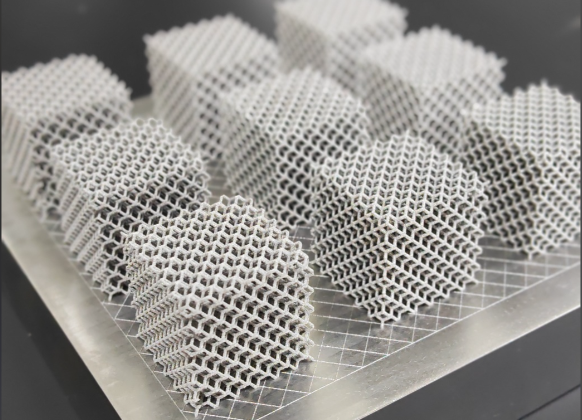

Thermoplastic Polyurethane (TPU):

The current mainstream material, laser-sintered from powder form. The finished product is lightweight, wear-resistant, and offers excellent rebound properties, widely used for midsoles in athletic shoes.

Bio-based Nylon and Eco-Friendly Materials:

Some brands utilize printing materials made from algae extracts or recycled plastics, upholding environmental principles while ensuring wearability.

These materials are not only safe and non-toxic but also achieve traditional shoe functions like cushioning, support, and breathability through precise structural design—often outperforming conventional alternatives.

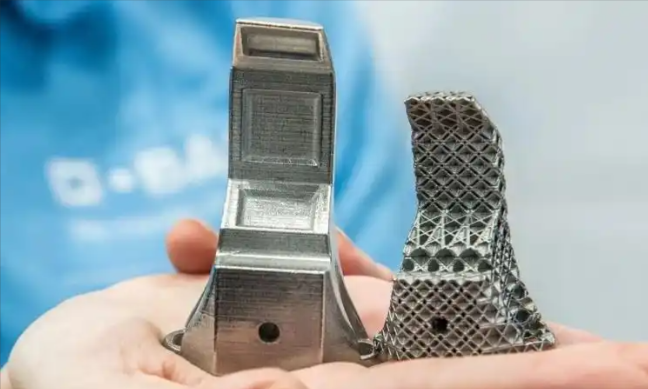

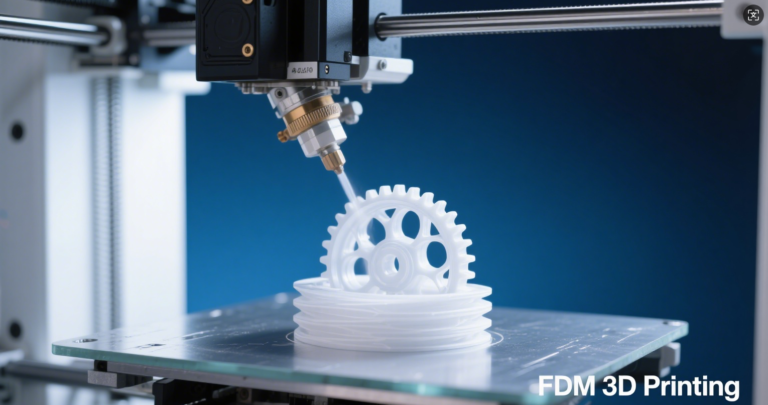

Process: How to 3D Print a Real Shoe?

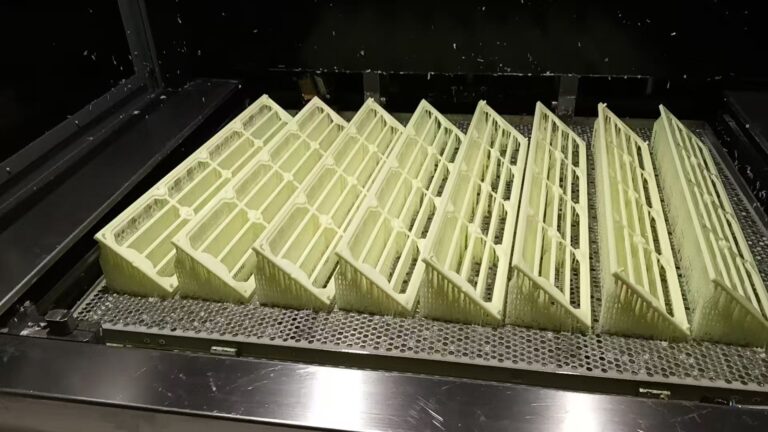

Upper:

Using SLA (stereolithography) or MJF (multi-jet fusion) technology, extremely lightweight, openwork, breathable uppers can be printed, perfectly enveloping the foot while providing outstanding ventilation.

Integrated Printing:

A select few high-end concept shoes have achieved integrated printing of the midsole and upper, eliminating assembly and completely eliminating glue bonding for enhanced sustainability and durability.

After printing, each shoe undergoes post-processing steps including sanding, cleaning, and assembly to ensure comfort and safety during wear.

Application Areas: Who is Wearing 3D-Printed Shoes?

3D-printed shoes have long left the lab and entered real-world life and sports arenas:

Custom Performance Footwear for Elite Athletes:

Brands like Nike and Adidas provide elite athletes with fully personalized 3D-printed midsoles. By scanning foot geometry and analyzing movement dynamics, they print soles perfectly matched to each athlete’s power delivery patterns, maximizing performance while preventing injuries.

Orthotic Insoles for Medical Rehabilitation:

This represents the earliest and most mature application of 3D printing. Doctors scan patients’ feet to print orthotic insoles that precisely conform to their arches and foot contours, effectively correcting gait and alleviating pain. This demonstrates both the safety and functionality of wearing these insoles.

Limited Editions and Personalized Customization for Mass Consumers:

Numerous brands release limited-edition 3D-printed sneakers, attracting consumers with futuristic designs and novel experiences. Users can even customize exclusive patterns and structures via apps, truly achieving “a pair of shoes made just for you.”

Solutions for Special Populations:

For individuals with abnormal foot shapes (e.g., extremely wide feet, high arches), 3D printing is a game-changer. It enables genuine “custom-fit-to-foot” solutions, addressing the pain point of shoe shopping difficulties.

What’s It Like to Wear 3D-Printed Shoes?

Those who’ve tried them commonly report:

Exceptionally Lightweight: Hollowed-out structures drastically reduce weight.

Noticeable Cushioning: Mesh midsole provides a unique “squishy” feel and energy return.

Strong Support: Perfectly conforms to foot shape, like a second skin.

Conclusion: 3D-printed shoes aren’t just wearable—they represent the future of footwear.