When traditional trophies meet 3D printing, every moment of honor deserves to be one-of-a-kind

Today, with the maturation of 3D printing technology, the trophy customization industry is undergoing a revolutionary transformation. From corporate award ceremonies to campus competitions, from esports tournaments to charitable recognition events—every moment of honor can now have its own unique vessel.

I. Materials: Beyond Metal, Textures Surpassing Imagination

Traditional trophies primarily rely on metal and crystal, limiting material choices. 3D printing technology breaks these boundaries:

Photopolymer Resin: Offers high precision and smoothness, enabling intricate details and complex curves—ideal for artistic designs.

Nylon Material: Lightweight yet durable with a subtle matte finish, perfect for modern minimalist trophies.

Metal Materials: Including stainless steel and aluminum alloys, these can be printed directly or used to create 3D-printed casting molds. They preserve the metallic feel while enabling more freeform shapes;

Multi-Material Hybrids: Supports combining transparent and solid colors, as well as integrating soft rubber with hard materials in a single piece, greatly expanding design possibilities.

II. Craftsmanship: The Finer Details Reveal Technological Brilliance

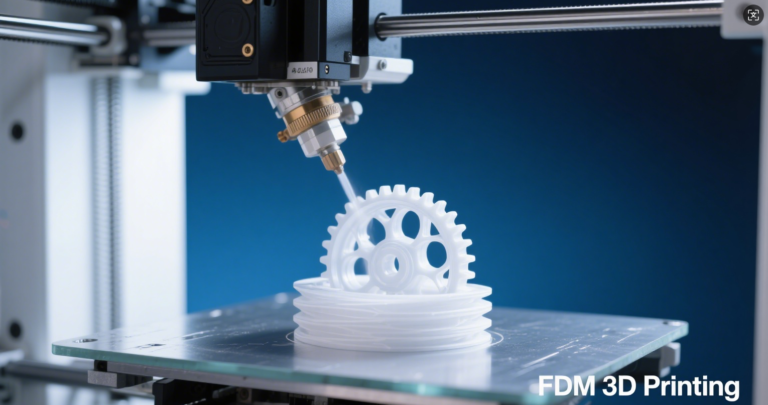

3D printing truly achieves “moldless forming” in trophy production, excelling particularly in the following techniques:

SLA Stereolithography: Ideal for ultra-precise trophies, perfectly reproducing sculptural details, engraved text, and openwork patterns;

SLS Nylon Sintering: Suited for monolithic molding, eliminating assembly hassles, especially for dynamic shapes and cantilevered structures;

Metal Binder Jetting: Combines metallic texture with intricate shapes, allowing post-processing like electroplating and polishing to elevate visual sophistication;

Full-Color Printing: Eliminates the need for post-coloring, directly achieving vibrant gradients, patterns, and logos for vivid visual impact.

III. Process: Efficient and Transparent, Making Customization Effortless

The 3D-printed custom trophy process is remarkably streamlined, delivering true “what you envision is what you get”:

Requirement Discussion: Beyond dimensions and text, we deeply understand the award’s significance, corporate culture, and recipient’s characteristics;

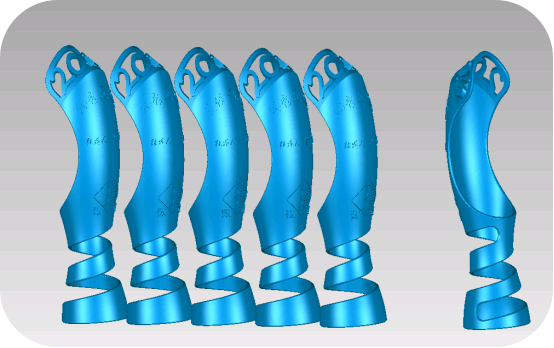

Creative Design: Designers model based on discussions, provide multi-angle renderings, and facilitate seamless real-time revisions;

Printing Production: After material and process selection, printing typically takes just hours to 2 days;

Post-Processing: Polishing, coloring, plating, assembly… Artisans meticulously hand-finish each piece, ensuring perfection in every detail;

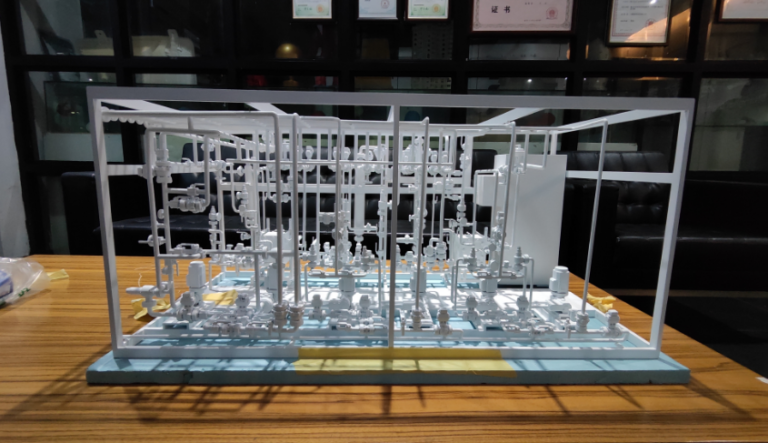

IV. Case Studies: Real Applications That Add Warmth to Recognition

Annual Gala for a Major Internet Company:

Custom trophies for the “Innovation of the Year” award winners transformed their product codes into abstract sculptures. The blend of transparent resin and metal exudes a futuristic tech aesthetic;

National College Esports League:

The championship trophy, modeled after a game character’s weapon, features a 1:1 replica design with integrated lighting effects, becoming a highlight of the event;

Volunteer Recognition for a Nonprofit Organization:

Shaped like the volunteer gesture logo and crafted from biodegradable PLA material, it embodies environmental values while being heartwarming and unique;

Museum Cultural Promotion Award:

Inspired by museum artifacts, the trophy employs 3D scanning and printing to recreate historical pieces, ensuring honors and heritage are passed down together.

3D-printed trophies transcend mere awards—they become artworks and treasured keepsakes. They elevate recognition beyond formality, transforming it into a medium that carries stories and conveys emotions.